Co-rotation compounding twin screw extruder for lab

Informations de base

Modèle: TSE-20, TSE-20

Description du produit

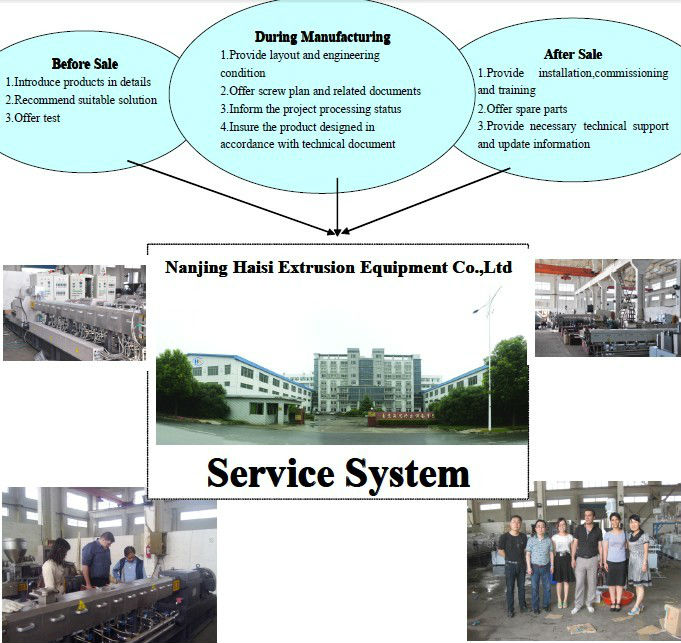

Dear Friend , welcome to Nanjing Haisi Extrusion Equipment Co.,Ltd , We are manufacturer of twin screw extruder, single screw extruder, pelletizing lines.

Co-rotation compounding twin screw extruder for lab

1.Application

TSE twin screw extruder line is able to process materials as follow:

---filling and modification

---general and fibre color masterbatch

---blending modification(rubber&plastic blending ,plastic alloy)

---functional masterbatch

---glass fibre or carbon reinforcement

---various cable material

---handling after dewatering

---powder coating and special material

2.Features

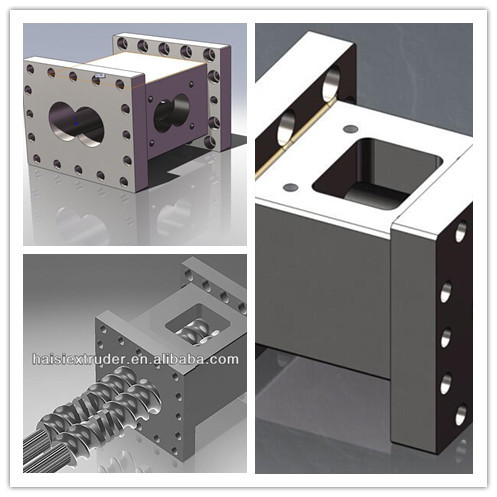

(1) Barrel

---.euro-style rectangle barrl, reflux refrigeration channel is optimized and disposed,which makes temperature difference in D areas smaller.

---.innovated design of heater tightened style insures high efficiency of heat transfer and high longevity of heater.

---.the material is used high quality nitrided steel ,corrosion proof or antifriction with correspounding process.

(2) screw

---.the screw is made of high tool steel 38 CrMoALA or W6Mo5Cr4V2 by special heat-treatment , which is possessed with high corrosion-resistat and high functions

(3)metering feeders

---.various metering feeders --- single screw ,twin screw ,hollow screw,forced-feeding, side- feeding.

(4) new-style gear transmission system

---new-style project of parallel three-axises driving makes the conve axis,convey

---chain,decelerate and torque get together ,which keep it compact ,and the key bearings are imported

---soakage and spraying lubriation integrate smoothly

---technics,strengthening of tooth face,so they can ensure high torque,high precision and low noise

---the selecte material of drive components is dainty,including super intention alloy cementiteing steel,cementiting and grinding.

(5) pelletizing system

---.various modes of pelletizing,such as water-cooling strand,air-cooling pelletizing,water-ring pelletizing,under water pelletizing

3.Parameter table

| Model | Screw Diameter D(mm) | L/D | Screw Rotation N(r/min) | Motor Power P(kw) | Screw Torque T(N.m) | Torque Rating | Output Q(kg/h) | |

| SHJ-20 | 22 | 32-44 | 600 | 5.5 | 43 | 7.5 | 0.5-10 | |

4.Certificate

5.Service system

other pelletizing machine

| Model | Screw Diameter D(mm) | L/D | Screw Rotation N(r/min) | Main Power (kw) | Torque(N.m) | T/N3 | Output Q(kg/h) |

| TSE-35A/B | 35.6 | 32-52 | 600 | 15-22 | 119 | 4.4 | 20-60 |

| TSE-40A | 41 | 32-64 | 400 | 22 | 263 | 6.4 | 65-110 |

| TSE-40B | 41 | 32-52 | 600 | 30 | 239 | 5.8 | 90-150 |

| TSE-50A/B | 50.5 | 32-52 | 500 | 45-55 | 430 | 5.4 | 135-270 |

| TSE-65A | 62.4 | 32-52 | 400 | 75 | 895 | 6.3 | 180-250 |

| 500 | 75 | 716 | 5.1 | 180-270 | |||

| TSE-65B | 62.4 | 32-64 | 600 | 90 | 716 | 5.1 | 200-300 |

| TSE-65C | 62.4 | 32-64 | 600 | 110 | 875 | 6.2 | 220-350 |

| TSE-75A | 71 | 32-56 | 400 | 90 | 1074 | 4.9 | 250-350 |

| 500 | 110 | 1050 | 4.8 | 300-420 | |||

| TSE-75B | 71 | 32-64 | 600 | 132 | 1050 | 4.8 | 350-550 |

| TSE-75C | 62.4 | 32-64 | 600 | 160 | 1273 | 5.8 | 400-600 |

| TSE-75D | 71 | 32-64 | 600 | 200-250 | 1990 | 9.2 | 500-1000 |

| TSE-95A | 93 | 32-64 | 500 | 250 | 2387 | 5.0 | 600-1000 |

| TSE-95B | 93 | 32-64 | 600 | 315 | 2506 | 5.3 | 800-1200 |

Groupes de Produits : extrudeuse à double vis co-rotative > Machine d'extrudeuse à double vis

Premium Related Products